About the Pallet Rack Mover System (PRM)

The PRM from Gondola Train is one of the most trusted tools for safely moving pallet racking systems. This equipment is built to move an entire pallet rack assembly as a single unit, instead of taking it apart piece by piece.

Using the PRM helps teams save time, reduce labor, and work more efficiently. Its heavy-duty design and user-friendly setup make it a reliable system for lifting and moving pallet racks in warehouses, distribution centers, and retail environments.

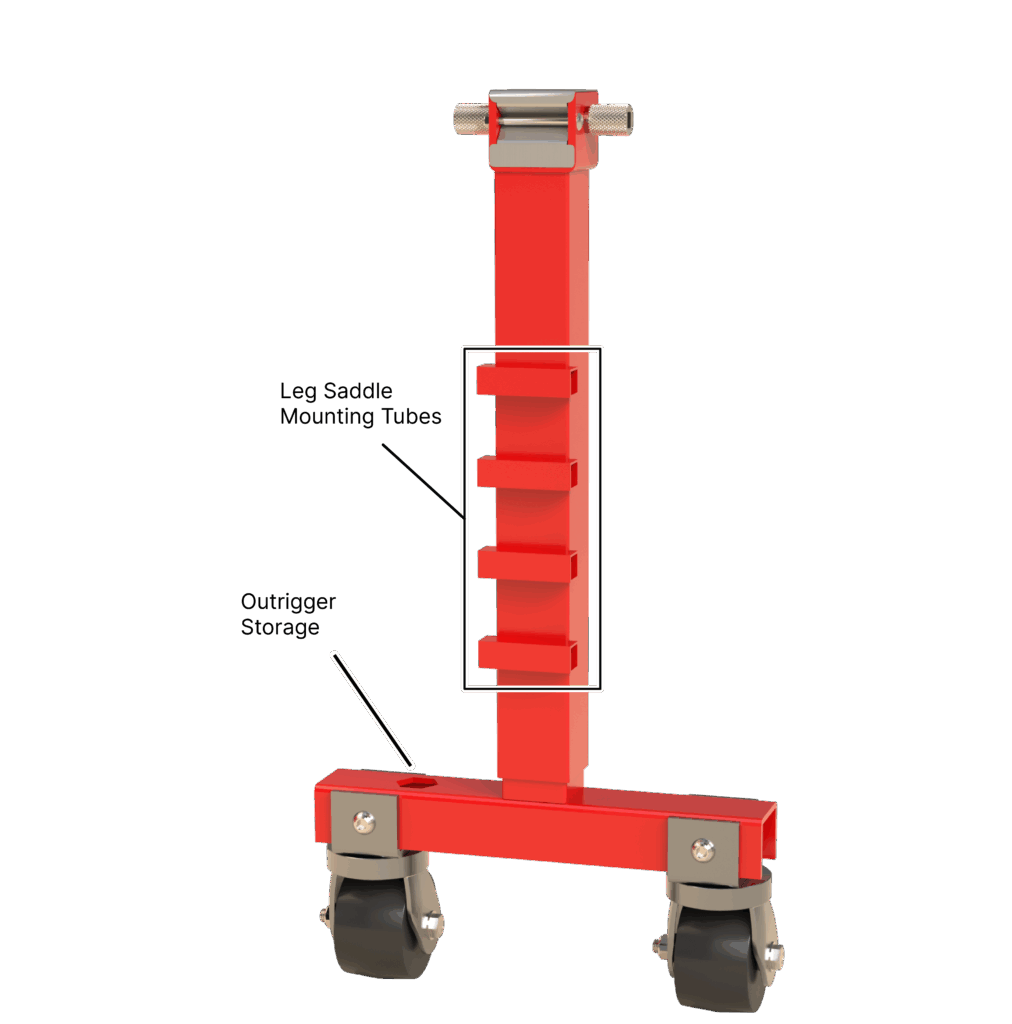

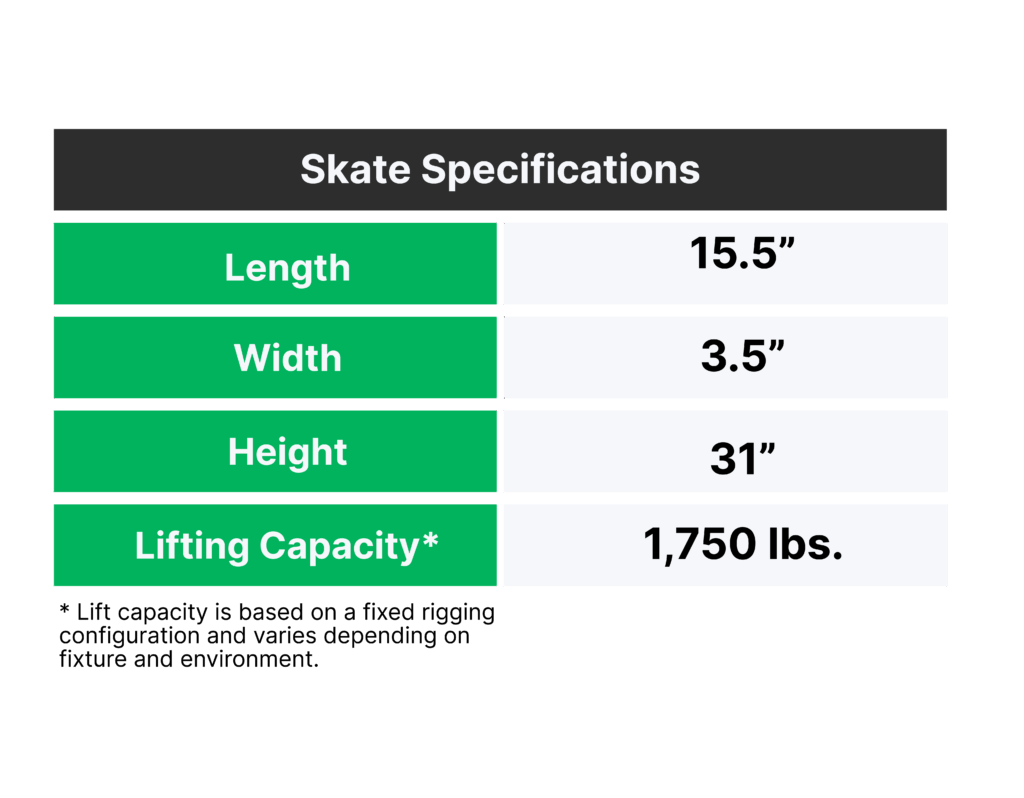

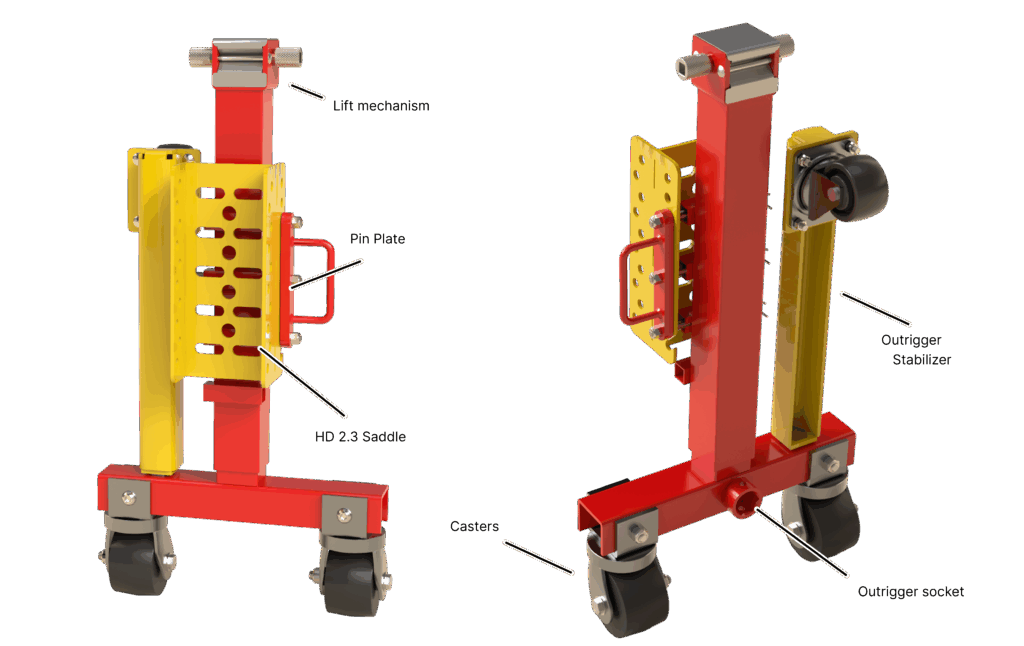

PRM Components

The PRM offers the following features:

Designed to move thousands of pounds safely, the PRM is suitable for industrial pallet racking and heavy warehouse loads.

System features and accessories

- Heavy duty casters: Being high-capacity, the swivel casters are made to hold the full weight of a loaded pallet rack. The low profile design adds stability and a smoother move across warehouse flooring.

- Lift mechanism: Operated by a drive ratchet, the PRM raises heavy fixtures with ease and precision.

- Workflow cart: Adding ease to staging, the mobile cart can add to transportation and setup when the box is not able to be placed in close proximity of the staging site.

- Quick install design locking system: For quick and secure connections, detent and hair pins are used to attach the components.

- Outrigger Stabilizers: A cantilever leg that prevents leaning or tipping during the mobilization process.

- PRM HD 2.3 saddle: Built as a universal yoke for the PRM system, this device allows users to lift nearly all types of pallet racking.